The Art Of Hand Finished Watches

The fine watchmaking of ROYTER

Hand Polished Watch Case

The polishing and brushing of every ROYTER Watch case is meticulously done by hand, exclusively by Dan himself. Each case demands hours of careful craftsmanship to ensure that every surface and angle reflects the highest standard of hand finishing. With perfection as the goal, each case is individually worked on to achieve the pinnacle of watchmaking excellence. Dan applies just the right amount of pressure with specialized tools to create perfectly balanced mirror-polished lugs and impeccably brushed case flanks, with hairline strokes that are flawlessly even. This process requires a steady hand, immense attention to detail, and years of experience.

Freehand Engraving

Every ROYTER Watch features a special hand-engraved winding rotor, crafted by a highly skilled artisan. Hand engraving is a complex, time-intensive, and rare art form that adds a distinctive character to each watch. The depth of each cut and the graceful curl of the lines act like a unique fingerprint—a personal signature that distinguishes every timepiece. Under a microscope, the smoothly carved lines reveal a brilliance that catches the light in a truly remarkable way.

Black Polished Screws

Even the a small detail like flat polishing of the screw head, change the overall look of the movement by enhancing visual appeal. First, the screw head is flat grained over special microfinishing film, following flat polishing process by rubbing the screw head over a zinc plate covered with some diamontine paste.The result is perfectly mirrored polished screw head that reflects black under different angle. We believe that hand finishing watch parts adds value to the watch when well executed, as every hand finished watch is unique in the sense that every hand finished part, every screw, is perfectly finished but still slightly different from the another.

REFINEMENT IN EVERY ELEMENT

Mastering the art of anglage takes years of practice, and achieving the perfect result is possible only by hand. The angle's surface must be uniform with parallel edges, and applying just the right amount of pressure is crucial—too much pressure can deform the component, while too little will result in an unclear, dull edge. The chamfering process beautifully enhances the rotor's shape, creating a stunning visual effect and an exceptional play of light. Since this delicate operation can only be done by hand, each piece is unique, with no two ever exactly alike. Anglage is one of the most intricate hand-finishing techniques, demanding extraordinary dexterity and skill.

Hand Finished Bridge

The chronograph bridge of ROYTER DR-02 automatic movement is hand decorated with haute horology finishing techniques such as anglage, beveling, Geneva stripes, and chamfering of the screw sinkholes. Each technique is a very delicate process that requires a specialized tools, steady hand and a highly trained eye.

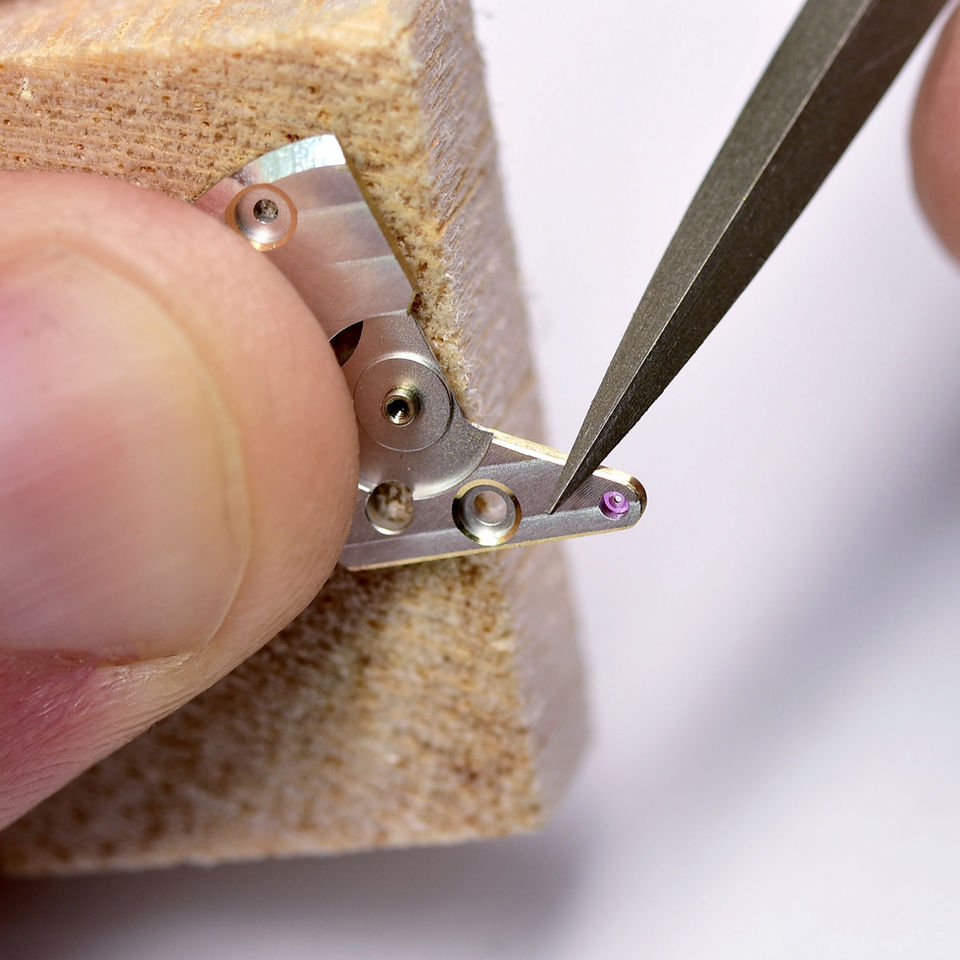

CHAMFERING & POLISHING

A concave chamfer around the screw head opening and jewels is carved by hand with a special carving tool. After, using a softwood sticks, the chamfers are individually polished using diamond paste. A process is very delicate that can only be done by hand and a highly trained eye. The freshly carved and polished screw holes are shining with beautiful diamond like reflections. It’s a purely aesthetic craft, which goes hand in hand with attention to detail and contributes to the overall refinement of a hand finished watch.

Cotes De Geneve

Côtes de Genève, or Geneva Stripes, is another traditional decorative finishing technique used in Royter Watches. This pattern features elegant, parallel waves applied to the top surface of the rotor, which not only enhances its visual appeal but also helps to trap tiny dust particles, protecting the movement from damage. The pattern is created using a specialized machine that moves a tool back and forth across the surface, engraving the distinctive stripes. Originating in the early 20th century, Côtes de Genève remains a timeless technique that beautifully catches and reflects light, giving the rotor a captivating sense of depth from every angle.

Anglage Beveling Technique

The Swiss traditional technique of anglage, a hallmark of high horology, is applied entirely by hand to remove the edges between the flank and surface of the winding rotor. Using a variety of handheld abrasive files, the rough edges are beveled into a smooth 45° angle, ensuring the chamfer maintains a consistent thickness throughout the component. The surface is then meticulously polished with a soft pegwood stick and diamond paste until a flawless mirror finish is achieved. This intricate, time-consuming process can only be mastered by an expert hand, as it requires weeks of precision with no margin for error.

Hand Crafted Leather Straps

Our bespoke leather straps are meticulously cut and stitched by a master artisan, with the utmost attention to detail. We source only the finest leather materials, offering a variety of colors and textures available on the market. Each two-piece strap is custom-made to ensure a perfect fit for your wrist, making every piece a unique work of art. Crafting a single watch strap takes many hours and involves more than forty individual steps. This process requires patience, exceptional precision, and a high level of skill.

To ensure the durability and longevity of our straps, we incorporate crocodile underlining padding for an ultra-luxurious feel. An exquisitely handcrafted leather strap enhances the experience of owning your timepiece. Whether you prefer red alligator skin or white lizard leather, our focus is on providing clients with the pleasure of complete bespoke freedom to create custom watch straps that perfectly complement your exceptional ROYTER Watch.

The Making Of Dials

The variety textures and colors that embellish Royter watch dials are the result of a mixture of high-level engineering, exquisite craftsmanship and pure chemistry. The challenging mastery of dial making demands strict knowledge of cutting-edge surface physics and chemistry as much as creative skill and understanding of a palette of colors. The naked eye nonetheless remains the final judge of what color may enrich a Royter dial.